Tunneling equipment refers to the specialized machinery and tools used to create underground tunnels for transportation, utilities, mining, or other purposes. These machines and tools are designed to efficiently excavate and remove soil, rock, or other materials while maintaining structural stability. The equipment varies depending on the geological conditions, tunnel size, and intended purpose of the tunnel.

Key types of tunneling equipment include:

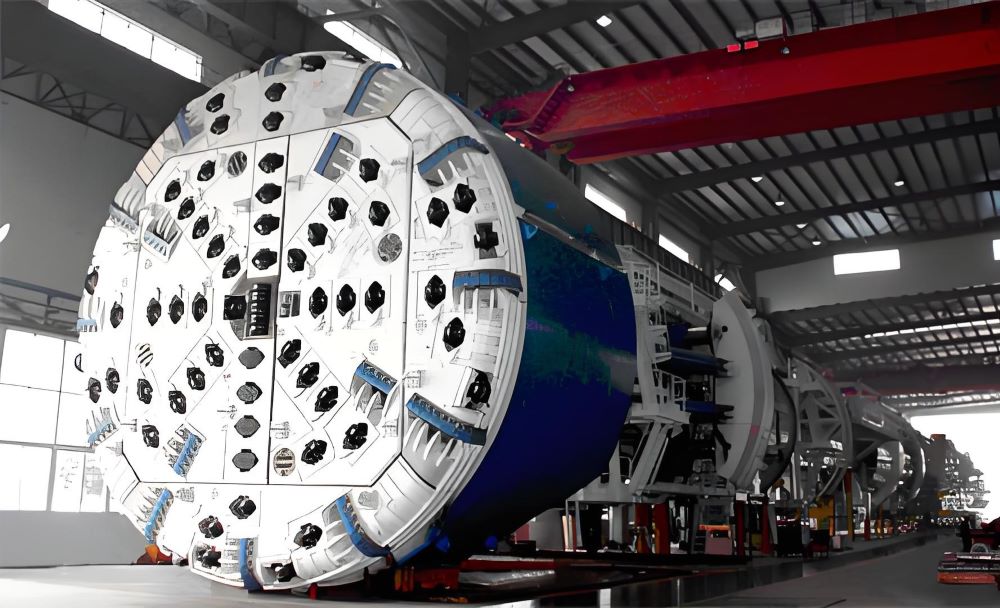

1. Tunnel Boring Machines (TBMs):

- Large machines that excavate tunnels by cutting through rock or soil.

- Equipped with rotating cutting heads, conveyor systems, and support mechanisms.

- Types include:

- Earth Pressure Balance TBMs (EPBs) for soft soils.

- Slurry TBMs for water-saturated ground.

- Hard Rock TBMs for rock formations.

2. roadheaders:

- Machines with a rotating cutting head used for excavating softer rock or mixed ground conditions.

- Often used in smaller tunnels or for precise excavation.

3. drilling and blasting Equipment:

- Used in hard rock tunneling where controlled explosions break rock into manageable pieces.

- Includes drilling rigs, explosives, and safety systems.

4. Shotcrete Equipment:

- Sprays concrete onto tunnel walls to provide immediate structural support.

- Often used in combination with other stabilization techniques like rock bolts or steel ribs.

5. Conveyor Systems and Muck Cars:

- Transport excavated material (muck) out of the tunnel.

- Essential for maintaining continuous excavation progress.

6. Grouting Equipment:

- Injects grout into the ground to stabilize or seal areas prone to water ingress.

7. Ventilation Systems:

- Provides fresh air and removes exhaust gases or dust from the tunnel.

8. Surveying and Navigation Equipment:

- Ensures the tunnel follows the planned alignment.

- Includes laser guidance systems, total stations, and GPS.

Tunneling equipment is vital for the successful completion of tunneling projects. It not only determines the speed and efficiency of the tunneling process but also affects the safety and quality of the tunnel construction. Advanced tunneling equipment can significantly reduce the time and cost required for tunneling projects, making them more feasible and economically viable.