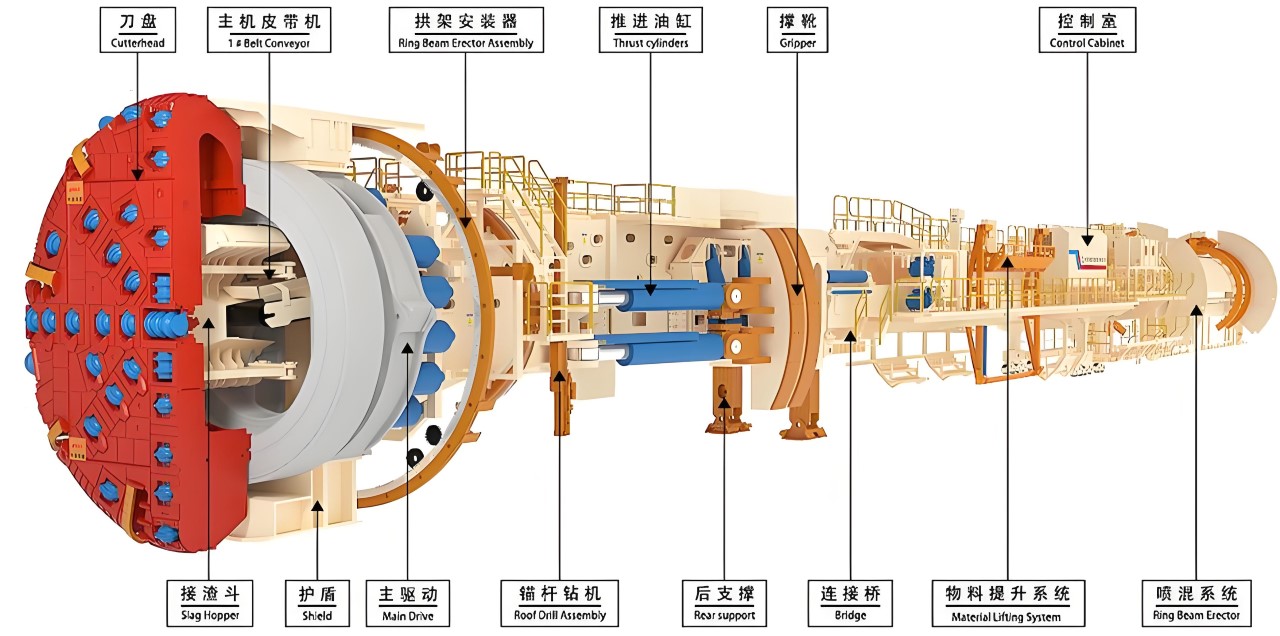

The Open-Type TBM (Open-Type TBM) is a heavy-duty machine suitable for tunnel construction in stable rock formations. Its structural design is centered around hard rock excavation, emphasizing an "open working space" and efficient rock breaking, mucking, and support coordination. Its core components and functions are as follows (comprehensive information):

I. Core Functional Systems

1. Cutting/Rock Breaking System

① Cutterhead Assembly: Mounted with disc cutters (hard rock picks), the cutterhead crushes rock through rotation and compression. The cutterhead structure includes scrapers, a bucket, and a mucking chute.

② Drive Unit: An electric or hydraulic motor drives the cutterhead. Some models are equipped with variable-speed or dual-speed motors to accommodate complex rock formations.

③ Telescopic Mechanism: The cutting head can be axially extended and retracted (such as in the EBZ series), reducing the frequency of equipment movement.

2. Support and Propulsion System

① Horizontal Gripper: Double-sided grippers press against the tunnel wall to provide reaction force and withstand the thrust and torque of excavation.

② Thrust Cylinder: Connects the gripper to the mainframe, driving the cutterhead forward.

③ Rear Support Leg: Stabilizes the machine body during shifting and prevents lateral slippage.

3. Loading and Muck Discharge System

① Scraper: A star wheel/scraper mechanism (driven by a hydraulic motor) collects rock debris. The angled design of the scraper facilitates bottom cleaning.

② Conveying Mechanism:

Primary Conveyor: A scraper conveyor (with a double chain structure) transports rock debris from the cutterhead to the rear.

Secondary Conveyor: A belt conveyor connects the primary conveyor to the mine car, enabling continuous slag discharge.

4. Support and Safety System

① Advanced Support Device: A movable front eave and support grid structure prevents face collapse (patented design).

② Auxiliary Support Equipment: An arch installer and anchor drill provide immediate reinforcement of the surrounding rock.

③ Dust Removal System: Internal/external spray devices (internal spray water pressure ≥ 3 MPa) combined with foam dust suppression.

II. Main Structure and Auxiliary Systems

1. Main Frame

① Main Frame: A box-shaped welded structure that carries the weight of all systems and is connected to the traveling section via high-strength bolts.

② Rotary Table: Articulated cutting arm with lateral swing controlled by a rotary cylinder.

2. Travel Mechanism

Crawler chassis (driven by a hydraulic motor) with drive wheels, supporting rollers, tensioning cylinders, and anti-skid brakes.

3. Hydraulic System

① Constant-power variable displacement pump and load-sensing valve block control cylinder lift/thrust and motor operation.

② Pressure cutoff protection prevents overload damage.

4. Electrical and Control System

① Explosion-proof electrical control box and intrinsically safe operating console with integrated methane power-off protection and cutting motor thermal monitoring.

② Laser guidance system for real-time tunneling trajectory correction.

The composition of the open-type tunnel boring machine is based on the core logic of "efficient rock breaking, flexible support, and rapid mucking". All systems work together to achieve safe and efficient tunnel excavation in hard rock formations.