As the "king of engineering machinery", the development trajectory of the full-face tunnel boring machine (TBM) confirms the rise of China's high-end equipment manufacturing industry. As early as the 1970s, companies such as Germany's Wirth and the United States' Robbins monopolized 90% of the global market share. At that time, projects such as the Guanjiao Tunnel of the Qinghai-Tibet Railway in my country were forced to import equipment at a sky-high price of 680 million yuan per unit. The turning point came in 2008, when China Railway Equipment and colleges and universities overcame the "rock breaking-slag removal-support" system integration problem, and the first composite shield machine "China Railway No. 1" rolled off the production line, marking the breakthrough of localization.

1. Breakthrough of the limit of super projects

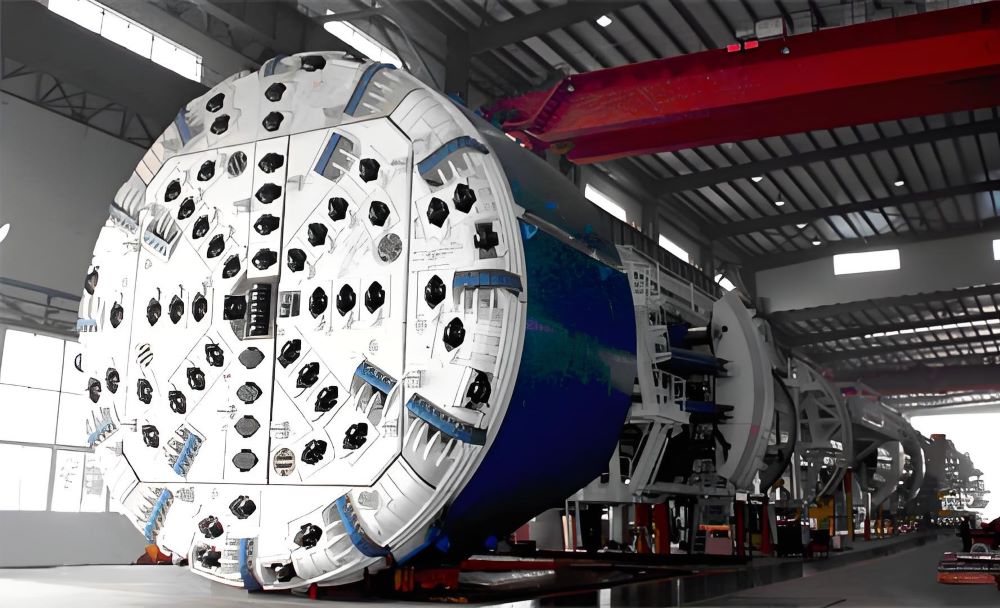

The "Plateau Pioneer" to be launched in 2025 demonstrates the new height of China's intelligent manufacturing:

① Environmental adaptability: equipped with a low-temperature start-up system (-40℃) and an altitude compensation device (5000m);

② Intelligent tunneling system: equipped with a 5G+MEC edge computing platform to achieve 0.1mm-level guidance accuracy;

③ Material revolution: The tungsten-cobalt-titanium alloy tool developed by Lingyuan Technology set a single-day tunneling record of 45.5m in the Tianshan Shengli Tunnel.

II. Collaborative innovation model of the industrial chain

1. Research on core components:

① Main bearing: Luoyang LYC breaks through 24,000 hours of life verification

② Hydraulic system: Hengli Hydraulics develops 50MPa ultra-high pressure pump valve group

③ Control system: Huawei Coal Mine Corps provides Hongmeng Industrial OS;

2. Construction paradigm change:

① The Liulin Tunnel of Tianlong Railway established a digital twin platform to realize the multi-dimensional linkage of geology-equipment-decision-making;

② Guangzhou Metro Line 18 applies the "tunneling brain" system to transform operating experience into 1,325 decision-making models;

III. Sustainable development challenges and countermeasures

1. Green transformation:

① Electricity consumption: The current energy consumption per meter of tunnel is 38kWh, which is still 18% away from the EU 2027 standard

② Carbon emissions: Develop hydrogen fuel cell power system, and the Guangzhou-Huacheng intercity project pilot reduces emissions by 41%

2. Intelligent bottlenecks:

① Geological prediction accuracy: The existing AI model is only 76% in complex fault zones

② Solution: Establish a million-level geological database and integrate InSAR satellite remote sensing data

3. International layout:

① The market share in Southeast Asia is less than 15%, and it is necessary to break through the certification barriers such as CE and UL

② Typical case: China Railway Construction’s Gudauri Tunnel project in Georgia set a record of 230 million euros for a single unit in the European market;