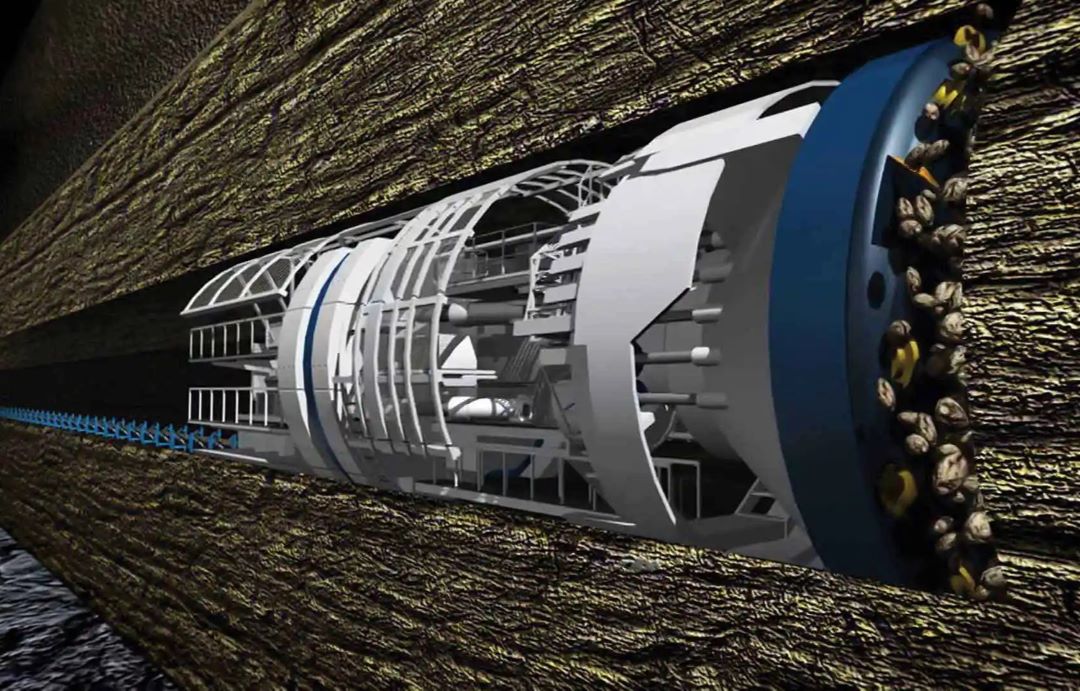

Open-type TBM is a full-section rock excavation equipment that uses a support mechanism to hold the tunnel wall tight to withstand the reaction force and torque of forward advancement. This type of TBM is particularly suitable for tunnel projects where the rock is not easy to collapse and the stratum is stable. In an environment with relatively broken strata, the open-type TBM needs to be supported by spraying mesh in time behind the cutterhead shield to ensure construction safety.

When the TBM works in broken strata, the finger-shaped grid plate behind the cutterhead will play a supporting role and construction will be carried out under the protection of the spraying mesh grid arch. If necessary, a steel arch will be installed at the bottom of the finger-shaped grid plate support to enhance the support effect. As the TBM advances, the support structure will move forward and perform initial support of sprayed concrete to ensure the stability of the tunnel.

In the construction of hard rock tunnels, especially in geological conditions dominated by II and III grade surrounding rocks, open-type TBMs perform well. After effective support, the equipment can also be used in soft rock tunnels. The TBM is equipped with auxiliary equipment such as steel arch installers and spray anchors to adapt to geological changes and improve construction efficiency and safety.

The open TBM is equipped with a top shield and a finger shield, which can be safely constructed under unstable surrounding rock conditions. When encountering locally unstable surrounding rock, the auxiliary equipment of the TBM (such as anchors, wire mesh, sprayed concrete and ring beams) can effectively reinforce the tunnel wall to ensure its stability. In the case of weak surrounding rock and broken zones, the TBM pre-consolidates the surrounding rock in front through advance drilling and grouting equipment, and then continues to excavate after it reaches self-stabilization.

When using an open TBM for construction, permanent lining is usually carried out after the entire line is connected. During the excavation process, the lithology changes of the tunnel wall can be directly observed, which is conducive to the depiction of geological maps. This real-time monitoring capability is particularly important when hydrogeological data is insufficient, and can give full play to the advantages of timely support of the New Austrian Tunneling Method theory.

In addition, small-diameter open-type TBMs can also be combined with the drill-and-blast method for the advance excavation of double-line (large-break) tunnels. In summary, open-type TBMs not only perform well under different geological conditions, but also can flexibly respond to various challenges in construction. They are an important technology in tunnel construction.