Shield Tunneling Machine is a heavy mechanical equipment used for tunneling. It ensures construction safety and efficiency by supporting the geotechnical structure around the tunnel during the tunneling process. The following is an introduction to the shield tunneling machine, its structural principle and 4 types.

1. Working principle

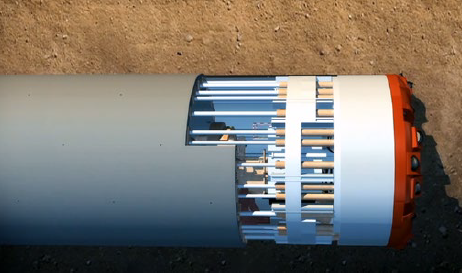

The shield tunneling machine cuts rock or soil through a rotating cutterhead. The cutterhead is equipped with multiple carbide cutters that can break rocks of various hardnesses. As the cutterhead rotates and advances, the cut rock or soil is transported to the conveyor belt at the rear of the machine and then transported out of the tunnel.

2. Shield structure

The shield is the front structure of the tunneling machine. It is made of steel plates and has sufficient strength and rigidity to support the tunnel wall and prevent collapse. In soft soil or unstable strata, the shield can also be used in conjunction with tunnel support systems (such as precast concrete lining blocks, steel arch frames, etc.) to ensure the stability and safety of the tunnel.

3. Types

Depending on the geological conditions, shield tunneling machines can be divided into many types, including but not limited to:

① Single Shield TBM: Suitable for relatively stable rock formations, capable of installing linings while tunneling.

② Double Shield TBM: Suitable for variable geological conditions, can switch working modes between stable and unstable formations.

③ Earth Pressure Balance TBM (EPB Shield TBM): Mainly used in soft soil formations, balancing groundwater pressure and ground load by controlling the soil pressure in the soil compartment.

④ Slurry Shield TBM: Suitable for high water pressure and complex geological conditions, using mud to stabilize the excavation face and discharge the soil.

Shield tunneling machines are widely used in underground engineering projects such as urban subways, railway tunnels, highway tunnels and water supply tunnels. Its advantages include fast construction speed, high safety and little impact on the surrounding environment.