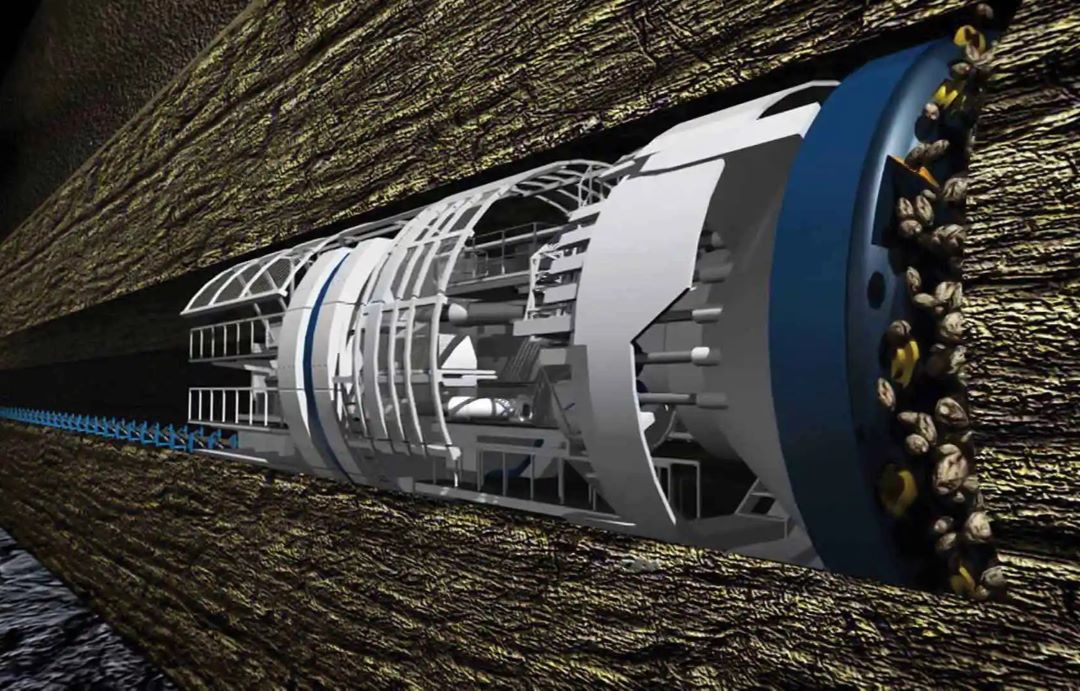

What safety hazards may the tunnel boring machine encounter during construction? Let's talk about the following safety hazards that may be encountered when using the tunnel boring machine for construction:

I. Equipment system failure hazards

1. Failure of mechanical components

① Long-term operation causes wear or aging of key components such as the cutting head and crawler, which may cause equipment loss of control, collapse or mechanical injury accidents.

② Leakage or unstable pressure in the hydraulic system may cause abnormal operation of the tunnel boring machine and increase operating risks.

2. Electrical system risks

Cable damage, poor wiring, motor overheating and other problems may cause electric shock and fire. If wire rope traction equipment is used in high-gas areas, it is more likely to trigger an explosion.

II. Geological and environmental risks

1. Geological disasters

① Water bursts, mud bursts, fault fracture zones or karst areas may cause working face instability and tunnel collapse. For example, a railway tunnel was buried by water and mud bursts due to insufficient karst geological exploration.

② Rock bursts may occur in high-altitude stress hard rock areas, and rock bursts and ejections threaten personnel safety.

2. Hazardous substance threats

① Dust (prone to pneumoconiosis) and harmful gases (such as methane and carbon monoxide) generated by excavation may cause poisoning or explosion.

② Failure to equip real-time gas detection equipment or insufficient ventilation will amplify the risk.

III. Human operation and management loopholes

1. Operational errors

① Untrained or fatigued operations can easily lead to misoperation, such as rolling over personnel in the blind area of the rotating fuselage, and improper control of the turning radius colliding with facilities.

② Illegal behaviors such as not locking the power supply during shutdown and knotting the wire rope.

2. On-site management defects

① Lack of safety warnings, unclear division of the operating area, and improper parking of equipment that hinders traffic (such as the case of excavators occupying the road in Xuhui District, Shanghai).

② Inadequate maintenance: Failure to regularly replace the hydraulic oil filter element and neglect the rust inspection of components.

IV. Derivative chain risks

1. Secondary accidents

Collapse may damage the supporting structure; failure of the hydraulic system may cause the working device to move unexpectedly and injure people.

2. Obstructed rescue

Failure to formulate emergency plans (such as evacuation routes and emergency shutdown procedures) will delay accident handling. The 88-Daysaka Tunnel was shut down for more than 300 days due to an imperfect solution for handling stuck machines.

V. Key prevention and control recommendations

1. Geological pre-exploration first

Use array acoustic wave advance detection technology to provide real-time warning of faults or karst areas; combine third-party testing and evaluation for complex areas.

2. Intelligent monitoring of equipment

Install sensors to monitor hydraulic oil temperature and electrical insulation status; promote electronic detonator hole-by-hole blasting technology to reduce vibration.

3. Personnel and system guarantees

① Implement operator graded certification and simulation drills, and enforce the wearing of protective equipment.

② Establish a key component replacement ledger and clarify the hidden danger rectification process.