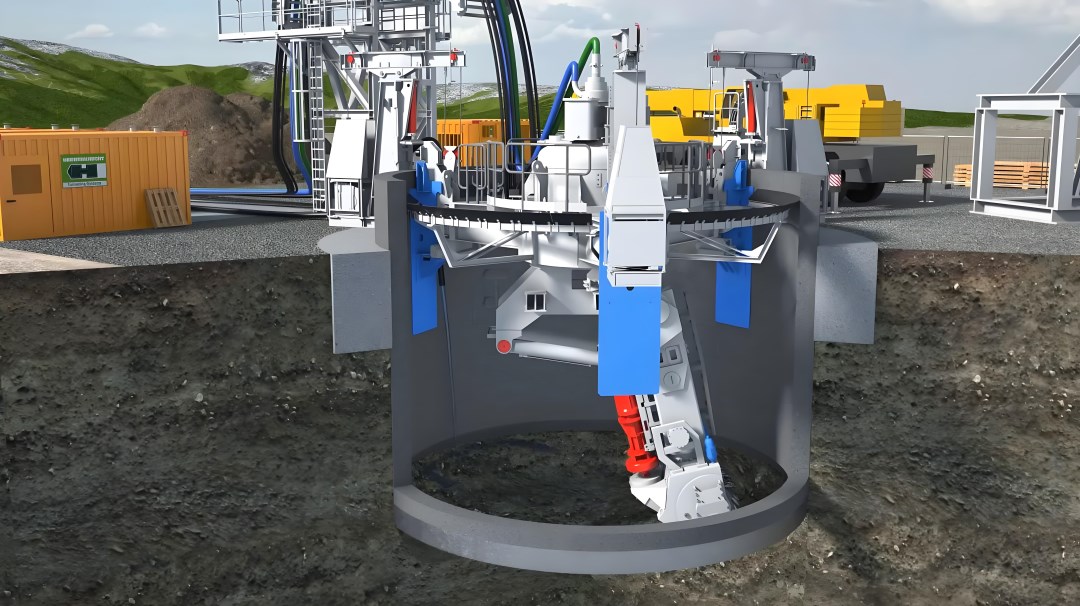

A shaft boring machine (TBM) is a type of mechanical equipment designed specifically for vertical shaft construction. It is primarily used for excavating vertical or near-vertical underground spaces such as tunnels, mines, and elevator shafts. This equipment efficiently performs tasks such as rock crushing, earth excavation, and material lifting.

A TBM typically consists of the following main components:

The cutting head: Attached to the front of the machine, it directly crushes rock or excavates soil. The cutting head may employ various operating principles, such as rotary drilling or impact crushing.

The propulsion system: This provides the driving force for the cutting head and typically includes a hydraulic motor, electric motor, or engine.

The support system: To ensure the stability of the working surface during excavation, TBMs are equipped with temporary support devices, such as hydraulic struts or steel supports.

The hoisting system: This system is used to lift excavated rock, soil, and other materials to the surface or a designated location. It typically includes a winch, chain, or wire rope.

The control system: This system monitors and controls all machine operations to ensure safe and efficient operation. Modern TBMs are also equipped with advanced automated control systems. During operation, a vertical shaft boring machine (TBM) uses a cutting head to cut rock or soil while a propulsion system provides power to move the machine downward or upward. A support system forms a temporary support structure at the working face, ensuring a safe working environment. A hoist system transports excavated material away from the working face. A control system monitors and manages the entire operation.

Due to the unique characteristics of vertical shaft engineering, this type of TBM requires excellent stability and the ability to adapt to diverse geological conditions. Furthermore, to meet safety regulations and environmental requirements, TBMs must be equipped with necessary safety features and emission control systems.