What are prestressed anchors? Prestressed anchors are key support components used in geotechnical engineering to actively reinforce rock and soil. By pre-applying tensile force (i.e., "prestressing"), the anchor generates a continuous compressive stress on the surrounding rock and soil, thereby restraining deformation and preventing collapse or instability. They are widely used in engineering scenarios such as foundation pits, slopes, tunnels, and mines.

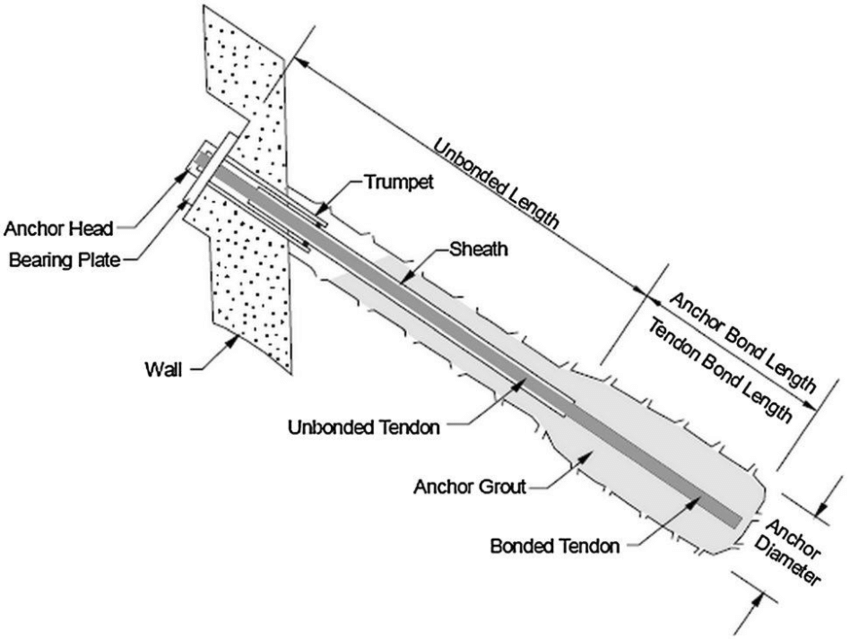

A prestressed anchor consists of four parts: the anchor head, the rod body, the anchoring section, and the free section. The anchor head is responsible for transmitting prestress and securing the structure or support system. Common forms include anchors, bearing plates, and pads. The rod body is the load-bearing core and is typically made of high-strength steel strands, threaded rebar, or composite materials. It must possess sufficient tensile strength and toughness. The anchor section is the key connection between the anchor rod and the rock and soil. Grouting (such as cement slurry or chemical slurry) creates a bond, transmitting the tensile force of the rod body to stabilize the rock and soil. The free section is the portion of the rod body between the anchor head and the anchor section. Its length can be adjusted according to project requirements to accommodate rock and soil deformation and ensure effective prestressing.

I. Main Classifications of Prestressed Anchor Bolts

Prestressed anchor bolts can be divided into various types according to different classification standards. The most common classifications are as follows:

1. Classification by Anchoring Method:

① Bonded Anchor Bolts: The rod body is bonded to the rock and soil using a binder such as cement slurry or resin mortar. They are suitable for permanent projects (such as dam reinforcement and permanent tunnel support) and offer stable anchoring force and high durability.

② Mechanical anchors: These rely on mechanical devices (such as expansion shell anchors and wedge-type anchors) to create anchoring force through compression with the hole wall. They are fast to install and are suitable for temporary projects (such as temporary foundation pit support and tunnel rescue).

2. Classification by rod material:

① Steel anchors: These include high-strength steel strand anchors (high tensile strength and flexibility, suitable for large-span tunnels) and threaded steel anchors (high rigidity, suitable for rigid support applications such as foundation pits and slopes).

② Composite anchors: These include fiberglass and carbon fiber anchors, which are corrosion-resistant, lightweight, and offer excellent insulation properties. They are suitable for coastal environments with high salinity, high groundwater levels, or projects requiring corrosion protection.

3. Classification by load characteristics:

① Tension anchors: These primarily bear tensile forces and are the most commonly used type in engineering, suitable for most geotechnical reinforcement applications.

② Pressure-type anchor bolts: Their special structure allows the anchoring section to withstand pressure. They are suitable for soft soils and rock with developed fractures, reducing the risk of rod corrosion.

II. Engineering Applications of Prestressed Anchor Bolts

1. Slope Reinforcement: Prestressed anchor bolts (often combined with lattice beams and retaining walls) are used on highway and railway slopes, as well as mine spoil dumps and water conservancy slopes, to resist the downward force of the rock mass and prevent landslides and collapses. This is exemplified by the reinforcement of some steep slopes on the Sichuan-Tibet Highway.

2. Tunnel and Underground Engineering Support: During shield tunnel segment assembly and mountain tunnel excavation, prestressed anchor bolts can be combined with shotcrete and steel supports to form a combined support system, controlling deformation of the surrounding rock and reducing convergence. This system is particularly suitable for tunnels with weak surrounding rock and large cross-sections, such as the support design of some Beijing Metro tunnels.

3. Foundation pit support: In deep foundation pit excavation for urban high-rise buildings and underground pipeline corridors, prestressed anchor rods connect the foundation pit retaining piles (or underground diaphragm walls) to the deep stabilized soil layer, balancing the earth and water pressure outside the foundation pit, preventing excessive deformation of the retaining structure, and protecting the safety of surrounding buildings and underground pipelines. This is exemplified by some ultra-deep foundation pit projects in Shanghai's Lujiazui area.

4. Dam and structure reinforcement: In slope reinforcement of earth and rockfill dams, as well as in the foundation reinforcement of older factories and bridges, prestressed anchor rods strengthen the connection between the dam body or structural foundation and the rock and soil, enhancing overall stability. This was exemplified by the dam slope reinforcement project at a Yellow River hydropower project.

As an active reinforcement technology in geotechnical engineering, prestressed anchor rods, with their efficient and reliable reinforcement, have become a critical component in ensuring project safety. From highway slopes to underground tunnels, from foundation pit support to dam reinforcement, they play an irreplaceable role in a variety of complex engineering scenarios. With the continuous innovation of technology, prestressed anchor rods will further adapt to the engineering needs of more difficult and complex environments, and provide more solid technical support for the safe and efficient construction of geotechnical engineering.