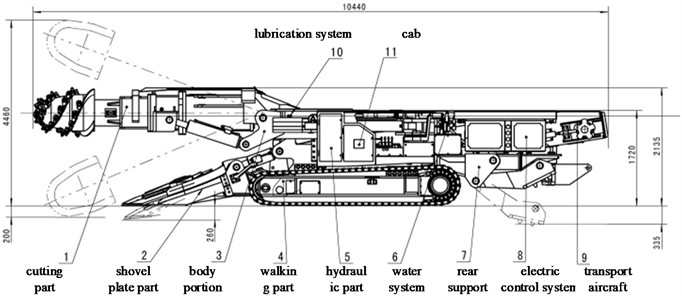

A boom roadheader is a core piece of equipment that enables integrated "rock breaking, loading, and transport" operations in underground projects such as coal mines and tunnels. Its structural design focuses on efficient tunneling and continuous operation. It consists of eight core systems/components, which work together to complete the entire process from rock cutting to material transfer. The following is a detailed analysis of each component:

I. The Eight Core Systems/Components of a Boom Roadheader

1. Cutting Mechanism (Core Tunneling Component)

The cutting mechanism is the "working head" of the roadheader, directly breaking rock or coal. It's like the machine's "arm + cutter," and determines tunneling efficiency and cross-section quality.

Core Components:

① Cutting Head: Equipped with multiple carbide picks (wear-resistant and impact-resistant), it cuts rock through high-speed rotation. Shapes vary, such as conical and hemispherical, depending on the tunneling cross-section required.

② Cutting Boom (Cantilever): Available in telescopic and non-telescopic versions, it can swing up and down, left and right (hydraulically driven), adjusting the cutting head's operating position to achieve tunneling in various cross-sections (e.g., rectangular, trapezoidal).

③ Cutting Motor/Reducer: Powers the cutting head. The motor's output torque is amplified by the reducer and then rotates the cutting head (typically with low speed and high torque, suitable for hard rock cutting).

Function: Directly crushes the rock mass to form the desired tunneling cross-section.

2. Loading Mechanism (Material Collection Component)

Cut rock debris/coal lumps must first be collected in the machine body. The loading mechanism performs this "shoveling" function and is the key link between cutting and transportation.

Core Components:

① Loading Blade: Located at the front of the machine body, below the cutting boom, it is shaped like a figure eight or arc. It is raised and lowered by a hydraulic cylinder to scoop up rock debris close to the ground.

② Starwheels (or Scrapers): symmetrically mounted on either side of the shovel blade, they rotate to push material from the shovel blade toward the conveyor mechanism in the center of the machine body, preventing material accumulation.

Function: Efficiently collects loose material after cutting, ensuring continuous material delivery to subsequent transport stages.

3. Transport Mechanism (Material Transfer Component)

The transport mechanism transports material collected by the loading mechanism backwards, directly transferring it to the accompanying mining belt conveyor or mine car, achieving continuous "excavation-slag discharge" operations.

Core Components:

① Scraper Conveyor (or Belt Conveyor): Located longitudinally along the machine body, extending from the center of the shovel blade to the rear end of the machine body, it conveys material via the circulating motion of a scraper chain (or belt).

② Tensioner: Adjusts the tension of the scraper chain (or belt) to prevent slippage or chain slack, ensuring stable transport.

Function: Quickly transfers material within the machine body to the external transport system, preventing material accumulation within the machine body and disrupting operations.

4. Travel Mechanism (Moving Components of the TBM)

The travel mechanism drives the TBM within the tunnel, enabling "adjustment of excavation position" and "transfer of the entire machine." It must adapt to the complex underground surface (muddy, uneven, and bumpy).

Core Components:

① Crawler Travel Mechanism (Mainstream): Consists of track shoes, drive wheels, guide wheels, and supporting rollers. It provides a large contact patch and strong grip, making it suitable for soft or uneven surfaces.

② Travel Motor/Reducer: Provides driving force for the crawler tracks, enabling forward/reverse and left/right turns (steering is achieved through the speed difference between the two crawler tracks).

③ Braking System: Locks the crawler tracks during shutdown to prevent the machine from sliding on sloped tunnels, ensuring safe operation.

Function: Drives the entire machine to adjust the cutting position or transfer to the next working surface after excavation is completed.

5. Hydraulic System (Power and Control Core)

The hydraulic system provides power to the machine's actuators, such as the cutting arm swing, blade lift, star wheel rotation, and crawler track travel. It functions as the machine's "muscle system" and controls the precision of each component's movements.

Core Components:

① Hydraulic Pump (Power Source): Driven by an electric motor, it converts mechanical energy into hydraulic oil pressure, providing high-pressure oil to the system.

② Hydraulic Cylinders (Actuators): These include the cutting arm swing cylinder, blade lift cylinder, and crawler track tensioning cylinder. The flow of hydraulic oil pushes the piston rods to extend and retract, achieving component movement.

③ Hydraulic Valves (Control Elements): These include reversing valves (control cylinder movement direction), relief valves (control system pressure to prevent overload), and throttle valves (regulate movement speed).

④ Oil Tank and Cooler: Stores hydraulic oil and cools heated hydraulic oil during circulation, ensuring a stable system oil temperature.

Function: Provides stable power to all moving parts, precisely controls movement amplitude and speed, and ensures flexibility during tunneling operations.

6. Electrical System (Control and Power Supply Core)

The electrical system is the "brain" of the tunneling machine, responsible for power supply, controlling the coordinated operation of various mechanisms, and providing safety protection to ensure reliable operation in the explosion-proof and dust-proof underground environment.

Core Components:

① Explosion-proof distribution box (control cabinet): Integrates circuit breakers, contactors, relays, and other components to control the start, stop, and speed regulation of the cutting motor, travel motor, hydraulic pump motor, and other components.

② Operation console: Located in the driver's cab, manual operation is achieved via handles (for controlling hydraulic valves) and buttons (for controlling motors). Some models are equipped with a remote control system.

③ Motors (power source): These include the cutting motor, travel motor, hydraulic pump motor, and transport motor. All are flameproof for mining use and suitable for hazardous underground environments such as gas and dust.

④ Safety protection devices: such as overload protection (automatically shuts down the machine when the motor is overloaded), leakage protection (prevents electric shock), and an emergency stop button (disconnects power in an emergency).

Function: Provides power to the entire machine, controls the coordinated operation of various systems, and ensures the safety of equipment and personnel.

7. Dust Removal System (Working Environment Optimization Component)

Tunneling operations generate large amounts of dust (rock dust, coal dust), which not only harms the health of operators but can also cause dust explosions. A dust removal system is essential for maintaining a healthy underground working environment.

Core Components:

① External Spray Device: Installed on the cutting head, blade, and other locations, this device sprays water mist through a high-pressure water gun to directly suppress the spread of dust generated by cutting.

② Internal Spray Device (select models): A water channel is built into the cutting head. Nozzles at the base of the cutting teeth spray water mist toward the cutting point, effectively reducing dust at the source and achieving higher efficiency.

③ Dust Removal Fan (Large TBM): Equipped with a bag filter or cyclone, the fan's negative pressure draws in dust from the air, filters it, and discharges the purified air.

Function: Reduces dust concentration in the tunnel, improves the working environment, protects the respiratory health of operators, and prevents dust explosions.

8. Frame and Auxiliary Equipment (Foundation and Support Components)

The frame serves as the foundation for the installation of core components, while auxiliary equipment provides safe and convenient operating conditions.

Core Components:

① Frame (Main Body): Constructed from welded high-strength steel plates, it offers exceptional rigidity, withstands the impact of cutting and the weight of various components, and ensures overall structural stability.

② Operator's Cab: Located in the middle or one side of the machine, it features a protective roof and tempered glass, providing the operator with a safe and unobstructed working environment. It is equipped with a seat, operating console, and lighting.

③ Lighting and Warning Devices: Explosion-proof lighting (to illuminate the working surface) and an audible and visual alarm (to alert nearby personnel during operation).

④ Lubrication System: Provides lubrication to transmission components such as the cutting reducer and travel reducer, reducing wear and extending service life.

Function: Provides a stable installation foundation for all systems, ensuring operator safety and convenience, and extending equipment life.

II. Collaborative Workflow of Various Components

1. The travel mechanism drives the entire machine to the working surface, and the brake locks in position.

2. The hydraulic system drives the cutting arm to swing, adjusting the cutting head to the initial cutting position.

3. The cutting motor starts, and the cutting head rotates to cut the rock. The dust removal system simultaneously sprays dust.

4. The cut rock debris falls onto the loading shovel, and the star wheel moves the material to the transport mechanism.

5. The transport mechanism transports the material backward to an external belt conveyor/mine car.

6. The electrical system coordinates and controls the actions of various mechanisms according to operational requirements (such as the cutting arm swinging to adjust the cross-section and the travel mechanism slowly advancing) until a section of tunnel excavation is completed.

Through the coordination of the above eight systems, the cantilever tunnel boring machine realizes integrated and efficient operations from "rock breaking" to "slag discharge", and is the core equipment for mechanized tunneling in modern underground engineering.