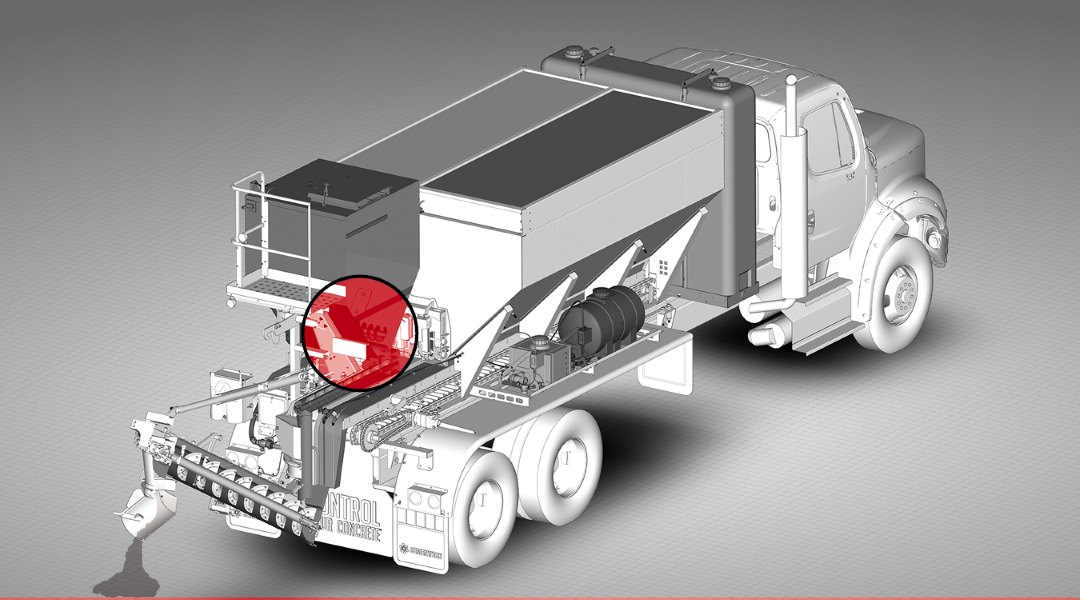

What is a volumetric concrete mixer? A volumetric concrete mixer (sometimes called a volumetric mobile mixer) is a truck- or trailer-mounted unit that carries the separate raw ingredients for concrete (cement powder, fine & coarse aggregates, water, and often admixtures or fibres) and then mixes them on-site in precisely the quantity needed.

Unlike a traditional ready-mix truck (which brings pre-mixed concrete from a plant), a volumetric mixer keeps sand, stone, cement and water separate until the moment of pour.

1. Advantages Over Traditional Mixers

① Waste Reduction: Eliminates over-ordering by producing exact quantities. Water usage for cleaning is 8–10 gallons vs. 200 gallons for barrel trucks .

② Freshness & Quality: Mixes are poured immediately, avoiding premature stiffening and ensuring uniform strength (up to 15% higher compressive strength) .

③ Flexibility: Ideal for small batches (e.g., 0.25 m³) and multiple mix types (e.g., colored, fiber-reinforced, shotcrete) in a single delivery .

④ Cost Savings: Reduces transportation costs and avoids minimum-order fees, saving 20–40% compared to ready-mix .

⑤ Environmental Benefits: Lower emissions due to reduced idling and fewer trips to batch plants .

2. Applications

Volumetric mixers excel in scenarios where traditional methods fall short:

① Small/Remote Projects: Rural construction, home foundations, or repairs where ready-mix trucks are impractical.

② Continuous Pours: Bridges, roads, and large slabs requiring seamless concrete placement.

③ Specialized Work: Gunite (shotcrete), decorative concrete (e.g., stamped or colored), and high-performance mixes for industrial use .

④ Urban Jobs: Tight spaces or congested areas where maneuverability is critical.

Volumetric concrete mixers redefine construction efficiency by combining on-demand production, waste minimization, and quality control in a single unit. Ideal for contractors, builders, and municipalities, they offer a sustainable, cost-effective solution for projects of all scales.