Tunnelheaders are categorized by head shape, primarily based on the structural form of the head used for excavation operations. Different head shapes determine their suitability for geological conditions, tunneling cross-section size, and construction efficiency. Currently, the mainstream classifications include cantilever, shield (including TBM), bucket wheel, and milling types. These types differ significantly in their head structure, operating principles, and application scenarios. A detailed introduction is provided below:

I. Cantilever roadheader

1. Head Shape Characteristics

The core of the head is a swingable "cantilever + cutting head" structure: the cantilever is a slender arm that can swing horizontally (left and right) and vertically (up and down) around the machine body. Mounted at the front of the cantilever is a "cutting head," typically conical or cylindrical in shape, covered with high-strength cutting teeth (such as carbide cutting teeth). The overall head shape resembles a "flexibly pivoting robotic arm + excavation tool."

2. Working Principle

The cutting head rotates at high speed (typically 20-60 rpm), using its picks to cut and crush rock and coal. Simultaneously, the cantilever swings, allowing the cutting head to cover various areas of the tunneling section, gradually excavating the designed cross-section (e.g., rectangular, trapezoidal, etc.). The crushed material is transported out via a scraper conveyor or transfer machine located beneath the machine body.

3. Applicable Scenarios

① Geological Conditions: Suitable for rock formations with a hardness below medium (Praetorian hardness f ≤ 8), coal seams, and semi-coal-rock tunnels. It is highly adaptable to geological variations (hard rock in some areas can be accommodated by adjusting cutting parameters).

② Cross-Sectional Dimensions: Primarily small to medium-sized sections (cross-sectional area 5-30 m2). The tunneling section shape (rectangular, trapezoidal, arched, etc.) can be adjusted as needed without replacing the core components of the head.

③ Construction Scenario: Underground coal mine recovery and preparation tunnels, auxiliary tunnels in metal mines, and auxiliary excavation in highway/railway tunnels (such as connecting passages).

4. Core Advantages

① High Flexibility: The wide swing range of the boom enables "all-around, variable-section" tunneling, eliminating the need for a pre-customized fixed-section head structure.

② Low Cost: The machine body structure is relatively simple, resulting in lower equipment procurement and maintenance costs than shield/TBMs. The machine also requires less worksite space, making it easy to assemble and move within narrow tunnels.

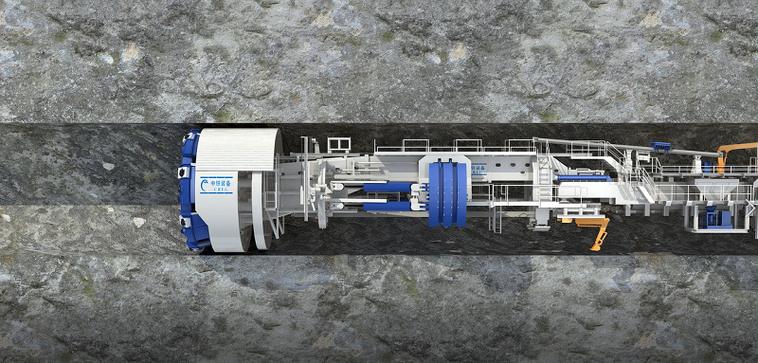

II. Shield Tunneling Machine (including TBMs)

1. Head Shape Characteristics

The head is a large, circular (occasionally rectangular or horseshoe-shaped) integrated "cutting head + shield" structure:

① The front end is the "cutting head," a disc-shaped structure (3-15m in diameter, with a maximum diameter of over 20m). The disc is covered with cutting tools (hoses, scrapers, cutters, etc., selected based on the geology) and is the core excavation component.

② A "shield" (including an earth pressure balance shield and a slurry balance shield) is connected to the rear of the cutterhead. This cylindrical shield wraps around the front of the machine, supporting the excavation surface and preventing collapse. Its overall head resembles a "giant disc with a protective shell."

2. Working Principle

① The cutterhead rotates at high speed, driven by hydraulics or an electric motor. The cutterhead crushes and cuts the ground (soft soil, sand, hard rock, etc.) in front of it (the rollers crush and crush hard rock, while the scrapers cut soft soil).

② Excavation debris enters the machine through an opening in the center of the cutterhead and is transported outward by a screw conveyor (for earth pressure balance shields) or a slurry pipe (for slurry balance shields).

③ The shield simultaneously supports the excavation surface while segment assembly (precast concrete segments are spliced together to form the tunnel lining) is completed inside the machine, achieving integrated and continuous operations of "excavation, mucking, and support."

3. Classification and Segmentation

Based on their suitability for strata, shield tunneling machines (TBMs) can be further divided into "shield machines" (primarily for soft soil) and "TBMs (full-face hard rock tunneling machines)" (primarily for hard rock). The key difference between the two lies in the type of cutter:

① Shield machines: Primarily use scrapers and cutters, suitable for soft soil, sand, silt, and composite strata (containing a small amount of soft rock);

② TBMs: Primarily use roller cutters (disc cutters), suitable for hard rock strata (Praeter's hardness f ≥ 8), such as granite and quartzite;

4. Core Advantages

① High Efficiency: Continuous tunneling with full-face excavation, achieving daily advances of 10-30 meters (cantilever tunneling is typically 1-5 meters), suitable for long tunnels (≥ 1 km in length).

② High Safety: The shield directly supports the excavation face, eliminating the need for workers to be exposed to the excavation face, significantly reducing the risk of landslides. This is particularly suitable for soft soil and high water pressure strata.

III. Bucket Wheel Roadheader (Wheel Bucket Roadheader)

1. Head Shape

The head is a rotating excavation device composed of multiple sets of "wheel buckets": the wheel buckets are cylindrical, with multiple "buckets" (similar to a smaller version of an excavator bucket) evenly distributed around the circumference. These buckets are arranged in parallel or staggered configurations, giving the head a head shape resembling a "drum with multiple buckets." Some models are equipped with crushing tools (for handling small amounts of hard rock).

2. Working Principle

The wheel buckets are driven by a motor to rotate at a low speed (typically 5-15 rpm), directly digging and grabbing soft rock through the buckets. If hard rock is encountered, crushing tools on the wheel bucket edges first crush it, which is then collected by the buckets. The material is then carried to the side of the machine body and dropped through a discharge port onto a conveyor for transport.

3. Applicable Scenarios

① Geological Conditions: Suitable only for extremely soft strata, such as clay, sandy clay, siltstone (f ≤ 3), and coal slime. It cannot handle medium-hard or harder strata.

② Cross-Sectional Dimensions: Primarily small to medium-sized sections (cross-sectional area 3-15 m2), with excavation sections mostly rectangular or trapezoidal.

③ Construction Scenario: Excavation of extremely soft coal seams in underground coal mines, mining of soft strata in non-metallic mines, and excavation of soft strata in underground engineering projects (such as underground diaphragm wall guide trenches in foundation pit support).

4. Core Advantages

① High Excavation Efficiency: The bucket directly grabs the material, eliminating the secondary "crushing-collecting" process of the cutter head. This results in a faster excavation of soft materials than cantilever excavators.

② Low Energy Consumption: High-speed cutting and crushing are not required, resulting in low motor load. Energy consumption per unit of work is 15%-30% lower than that of cantilever excavators.

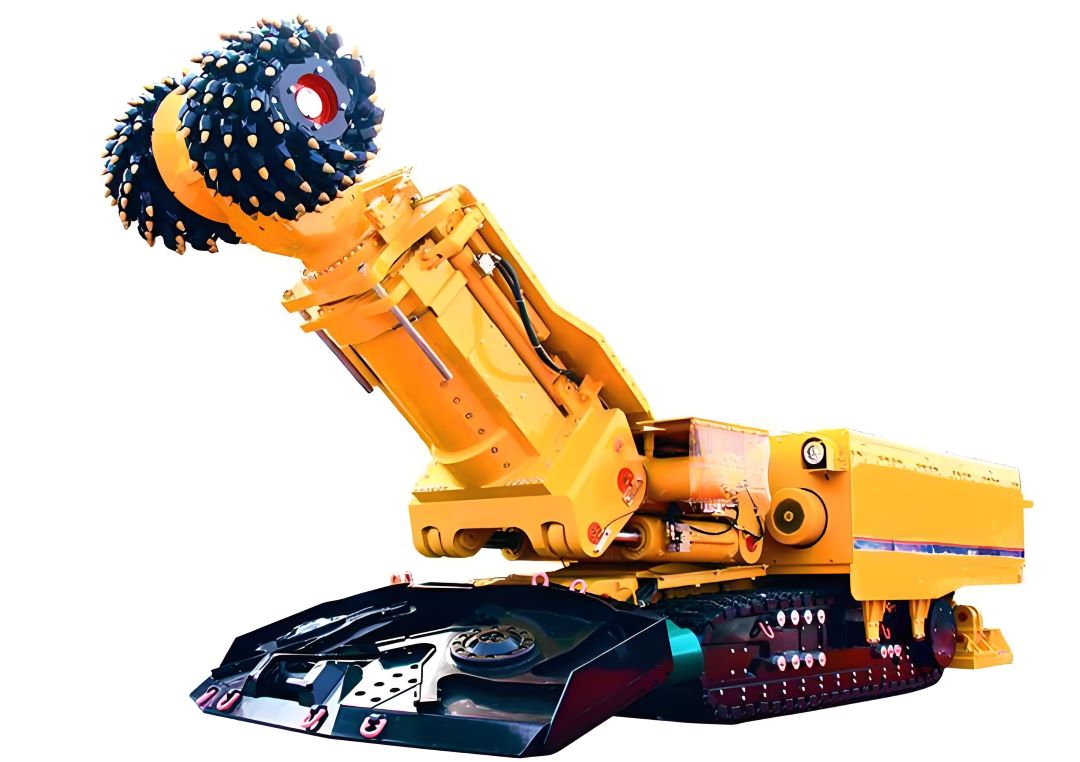

IV. Milling Roadheader

1. Head Shape Features

The head consists of a "milling drum/milling cutterhead + fixed frame" structure. The milling components come in two forms: one is similar to a "wide drum" with a surface covered with milling teeth; the other is a combination of "multiple sets of small milling cutters" arranged to cover the entire excavation section. The head frame is fixed to the front of the machine body and cannot swing widely like a cantilever type. The excavation direction must be adjusted by the movement of the entire machine body. The head shape resembles "a wide milling cutter fixed to the front of the machine body."

2. Working Principle

The milling drum/milling cutterhead rotates at high speed (30-80 rpm), milling and grinding the rock formation with its milling teeth (similar to the principle of a milling machine processing metal). Because the head frame is fixed, the machine body's propulsion system (hydraulic jacks) propels the milling components forward, while the machine body's steering mechanism adjusts the direction to excavate a fixed section (mostly rectangular or arched). The crushed material is transported out by a lower conveyor.

3. Applicable Scenarios

① Geological Conditions: Suitable for medium-hard rock formations (f=4-10), such as sandstone and shale. The milling method provides superior "grinding and crushing" effects on rock formations compared to the cantilever-type "impact cutting."

② Section Size: Mainly medium-to-large sections (cross-sectional area 10-40 m2), with fixed cross-sectional shapes (milling components must be replaced according to the design to adapt to different sections).

③ Construction Scenario: Main tunnel excavation for highway/railway tunnels (in geologically uniform medium-hard rock formations), underground powerhouses (such as hydropower station underground powerhouses), and main tunnels of large mines.

4. Core Advantages

① Smooth Excavation Section: Milling provides uniform cutting, and the flatness error of the excavation section can be controlled within ±50 mm (cantilever-type cutters are typically ±100 mm or more), reducing the amount of subsequent support work.

② Strong Stability: The head is fixed to the frame, resulting in minimal vibration during tunneling and minimal disturbance to the surrounding rock, making it suitable for projects requiring high excavation precision.

V. Summary of Key Differences Between Various Machine Types

① Cantilever: Swingable cantilever + cutting head, suitable for soft rock and coal seams (f≤8);

② Shield/TBM: Circular cutterhead + shield, suitable for soft soil/hard rock (all formations);

③ Bucket wheel: Multiple bucket wheels, suitable for extremely soft formations (f≤3);

④ Milling: Fixed milling drum/cutterhead, suitable for medium-hard rock (f=4-10);

In summary, the design of a tunnel boring machine head shape is essentially about "adapting to specific geological and engineering requirements": choose a cantilever for flexibility and versatility, a shield/TBM for long distances and large cross-sections, a bucket wheel for extremely soft formations, and a milling type for high-precision work in medium-hard rock. This is also the core logic behind the selection process.