drilling and blasting is one of the most widely used methods for rock excavation in mining, quarrying, tunneling, and large-scale construction projects. This technique combines precision engineering with controlled use of explosives to fragment hard rock, enabling efficient excavation and material handling.

1. What is Drilling and Blasting?

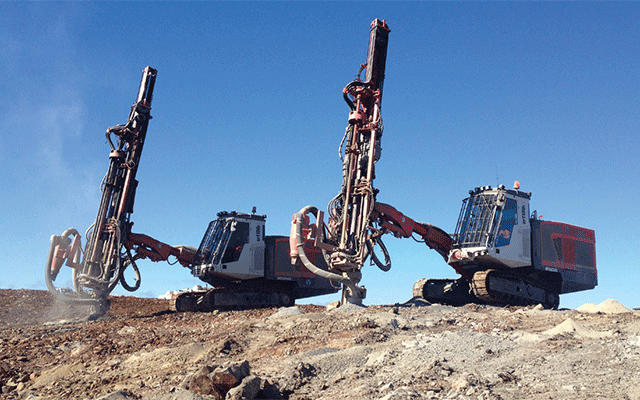

The process begins with drilling holes into the rock face using specialized drilling equipment. The depth, diameter, and spacing of these holes are carefully designed according to geological conditions and project requirements. Once drilled, the holes are charged with explosives and then detonated in a controlled sequence. The resulting shock waves break the rock into manageable fragments, which are then loaded, transported, or further processed.

2. Key Applications

① Tunnel Excavation: Primary method for shaping tunnels, especially in hard or variable geology [[1](), [9]()].

② Mining & Quarrying: Extracting minerals, ores, and construction aggregates [[4](), [6]()].

③ Civil Engineering: Foundation digging, road cutting, and dam construction [[10](), [13]()].

3. Key Steps in the Process

① Survey and Planning – Engineers study the rock formation, determine blast patterns, and ensure safety measures.

② Drilling – Boreholes are drilled with precision rigs to exact depths and alignments.

③ Charging and Stemming – Explosives are inserted, and stemming material (such as crushed stone) is placed to confine the charge.

④ Blasting – Detonation occurs in a controlled sequence, reducing vibration and maximizing fragmentation efficiency.

⑤ Muck Removal – Broken rock (muck) is cleared using loaders, trucks, or conveyors.

4. Advantages of Drilling and Blasting

① Efficiency – Capable of breaking large volumes of rock quickly.

② Cost-effectiveness – Reduces the need for extensive mechanical excavation.

③ Adaptability – Can be tailored to different geological conditions.

④ Productivity – Ensures continuous progress in large-scale projects.

Drilling and blasting remain indispensable in industries where rock excavation is critical. With advancements in technology, the method continues to evolve, offering greater precision, safety, and efficiency. Whether in mining, quarrying, or civil construction, drilling and blasting provide the foundation for progress in modern infrastructure and resource development.