In the construction process of underground engineering, after excavation, the importance of initial support is self-evident in ensuring structural safety and effectively controlling the release of surrounding rock stress and deformation. Among these, the erection frame and anchor bolts act like "injections to reinforce" the tunnel, while grouting and shotcreting are like "protective clothing" for the tunnel.

With the rapid development of tunnel construction technology in my country, the mechanization of tunnel construction and its supporting construction techniques have made significant progress. Lanhi has kept pace with the development of tunnel construction, developing and deploying multiple integrated arch-anchor trolleys. In 2025, the project "Key Technologies and Applications of Integrated Arch-Anchor Rapid Construction Equipment for Tunnels," jointly developed by Lanhi and Southwest Jiaotong University, won the second prize of the "Sichuan Provincial Machinery Industry Science and Technology Award." Lanhi's arch-anchor trolley is gradually becoming a comprehensive tool for the mechanized operation of erecting arch anchor bolts in tunnel construction.

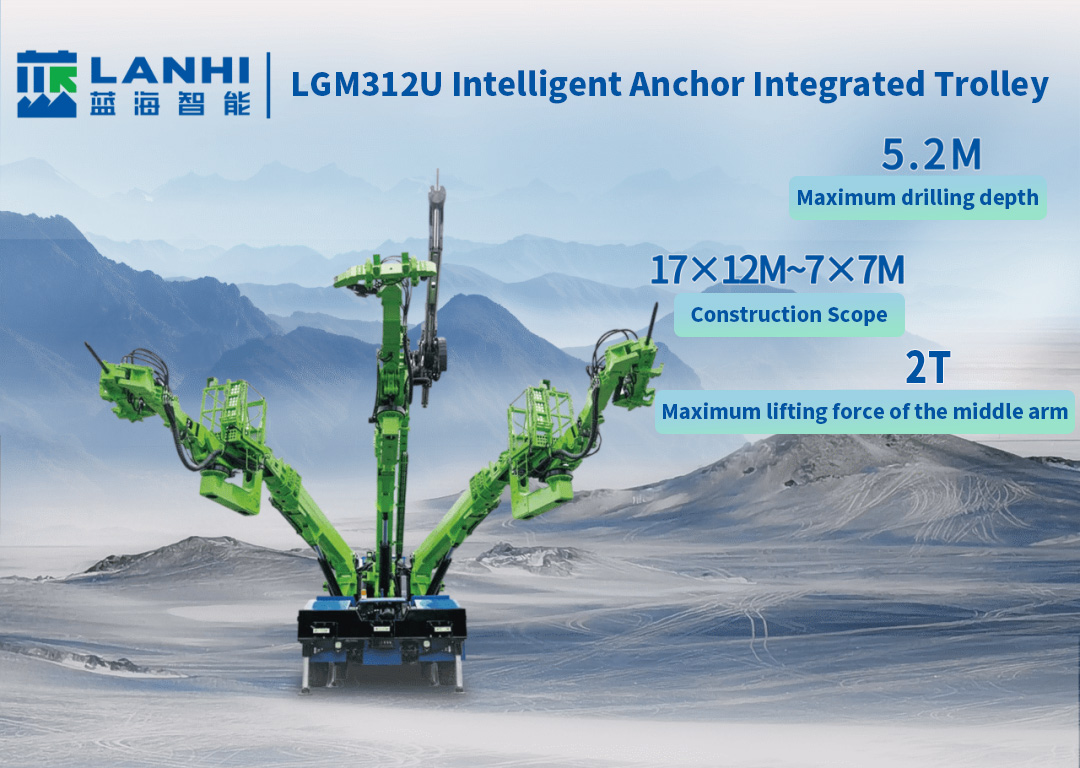

Lanhi's integrated arch-anchor trolley, a marvel of engineering, delivers superior tunnel construction.

The intelligent integrated arch-anchor trolley, after multiple iterations, integrates functions such as surveying and setting out, under-excavation work, arch frame installation, anchor mesh installation, advanced support, system anchor bolt construction, and anchor bolt grouting (optional). It can mechanize multiple processes, providing a highly efficient solution for initial support. The advantages of the Lanhi arch-anchor trolley mainly include the following six points:

1. One-hour erection, reducing safety risks

The intelligent integrated arch-anchor trolley combines multi-frame prefabrication and folding arch frame installation methods. The arch frames are pre-connected in the factory for use as multiple arch frames, and the connecting bars and mesh are pre-welded to reduce working time inside the tunnel. The prefabricated arch frames are then transported to the tunnel face.

After the intelligent integrated arch-anchor trolley arrives on site, the erection can be completed in about one hour, significantly improving construction efficiency. Furthermore, during arch frame installation, workers are protected by the mesh and connecting bars of the entire arch frame, greatly reducing safety risks in case of emergencies.

2. High Anchor Bolt Construction Efficiency: Achieving "Lightning Speed" in Tunnels

The intelligent arch-anchor integrated trolley is equipped with an 18kW rock drill, enabling rapid drilling. A single unit can independently complete anchor bolt installation, anchor bolt installation, and pre-support construction, reducing the time required for large machinery to relocate.

3. A 4-Person Team Can Complete a "One-Stop" Service for Initial Support

With only 4 people (2 operators and 2 assistants), the intelligent arch-anchor integrated trolley can complete the previously cumbersome arch frame installation, system anchor bolt installation, and (optional) grouting operations, significantly improving the overall construction efficiency of the initial support phase.

4. Extendable Suspended Platform for Multi-Purpose Operations

The extended suspended platform offers ample space and high safety, accommodating anchor bolt installation and auxiliary explosive loading operations.

5. Hydraulic Breaker + Welding Machine: Speeding Up Arch Erection and Clearing Obstacles

The equipment is equipped with a hydraulic breaker and welding machine, enabling under-excavation and welding operations, making it easier for operators to learn.

6. Intelligent (optional): Remotely viewable, commandable, and controllable

Construction is supported by a cloud management system including real-time location tracking, real-time monitoring, hazard identification, command transmission, and remote monitoring via an app.